Manufacturing – Complete Visibility and Traceability in Your Production Process

Modern manufacturing demands precision, efficiency, and full control at every stage. From complex components to finished goods – every detail matters. The SolutionsInc Manufacturing Module is a comprehensive tool that allows you to track multi-level Bills of Materials (BOMs) for both finished goods and sub-assemblies. Thanks to integration with sales and stock, you’re always one step ahead, anticipating upcoming production jobs and pre-planning your production queues. Estimate raw material requirements and initiate timely requisitions to keep processes flowing smoothly. Ensure accurate valuation of produced items, along with rigorous quality checks, before back-flushing is carried out.

Key Elements of the SolutionsInc Manufacturing Module:

- Efficient Bill of Materials (BOM) Management

- Precise Production Planning

- Work Order Management

- Capacity Planning

- Streamlined Subcontracting Management

- Identification of Subcontracted Items

- Subcontracting Order Management

- Subcontracting Service Billing

- Manufacturing Reports and Dashboards

Efficient Bill of Materials (BOM) Management

The Bill of Materials (BOM) forms the core of every manufacturing operation, linking all processes back to its intricate details. In SolutionsInc, you can create and maintain comprehensive BOM records, precisely specifying raw materials in various quantities and Units of Measurement (UoMs), while clearly outlining the sequence of operations needed to transform them into finished goods. BOMs also serve as a powerful tool for estimating raw material and operation costs, enabling accurate calculation of the estimated value of finished items. This systematic approach helps in setting competitive sales prices for your products, ensuring profitability and market competitiveness.

Precise Production Planning

Building an effective production queue requires taking numerous factors into consideration, such as committed delivery dates to customers, and the availability of raw materials and sub-assemblies. SolutionsInc’s production planning module provides a step-by-step solution to identify items to be produced, fetch raw materials required via their BOMs, and check their availability across various warehouses. This enables you to raise requisitions for raw materials and initiate Work Orders accordingly, ensuring a smooth and uninterrupted manufacturing process.

Work Order Management

A Work Order is the key directive for the manufacturing team, outlining the production process as defined in the linked BOM. It serves as the central document, triggering raw material transfers from the warehouse, generating Job Cards for individual operations, and enabling the final stock adjustment for finished goods (backflushing). Sales teams can also refer to Work Orders to track production progress and keep customers updated in real-time. If production is like an orchestra, the Work Order is the conductor, coordinating all operations to ensure every action happens on time and in harmony.

Capacity Planning

Factory operating costs represent a significant portion of a company’s expenses. Hence, mismanaging the allocation of production jobs on Workstations can result in major losses. SolutionsInc’s capacity planning feature helps to track workloads on each workstation, enabling efficient scheduling of future production jobs. This ensures optimal utilisation of resources, accelerates production, and helps fulfil delivery commitments on time, boosting overall plant efficiency.

Streamlined Subcontracting Management

Focus on what you do best and let subcontracting handle the rest. By partnering with experts, you can leverage your core competencies while outsourcing specific tasks. SolutionsInc simplifies this process by allowing you to designate items as subcontracted to suppliers and manage all subcontracting orders within one centralised system. Track progress, ensure timely execution, and scale your subcontracting operations seamlessly. With SolutionsInc, you can efficiently collaborate with top suppliers, ensuring high-quality services while maintaining focus on your business strengths.

Identification of Subcontracted Items

Even when subcontracting, discipline and precise tracking are crucial to ensure quality and accuracy. In SolutionsInc, you can flag each subcontracted item and link it directly to a detailed Bill of Materials (BOM). This provides a clear list of materials to supply to the subcontractor, reducing logistical challenges and ensuring smooth operations.

Subcontracting Order Management

A Subcontracting Order in SolutionsInc captures all essential details, including the items to be subcontracted and their BOM. It acts as a central document for managing the transfer of raw materials to subcontractors and tracking the receipt of finished goods. When finished items are received, SolutionsInc ensures that the raw materials supplied to subcontractors are accurately accounted for and consumed. This streamlined workflow allows you to manage multiple subcontracting processes simultaneously, reducing delays, preventing stock pilferage, and maintaining quality standards with precision.

Subcontracting Service Billing

While subcontracting focuses on transforming raw materials into finished goods, accurate billing for the service provided is equally critical. SolutionsInc allows you to bill your subcontractors for their services, while the actual finished item received remains a stock item within your inventory. This ensures seamless creation of Purchase Orders, goods receipts, and invoices for subcontracting services. The workflow guarantees compliance with statutory regulations and ensures that payables are accurately recorded.

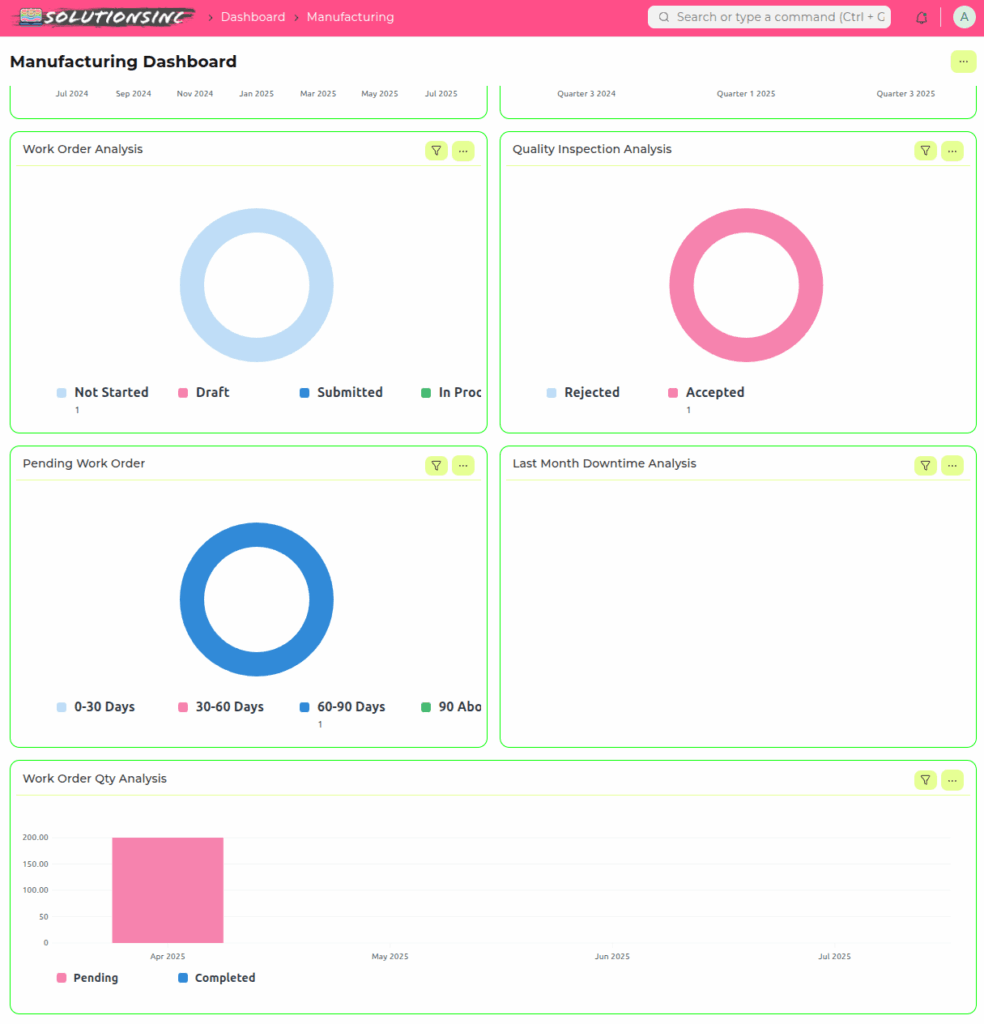

Manufacturing Reports and Dashboards

To gain a full overview of your manufacturing operations, SolutionsInc offers comprehensive reports and intuitive dashboards. Monitor production performance, analyse costs, track machine utilisation, and identify bottlenecks. This enables you to make informed decisions, optimise processes, and increase the profitability of your manufacturing activities.

The SolutionsInc Manufacturing Module is the foundation that allows factories to achieve 100% visibility and traceability in their production process, leading to increased efficiency, better cost control, and assurance of quality at every stage.